Textiles materials make the production of foams, carpets, fabrics and sandwich materials possible. Now caution should be applied when handling this machinery as it can be very hot or very cold, depending on what it’s being used for. We also offer custom-made textile equipment to meet your specific needs as well as general technical requirements. The handling and transfer of solutions between different workstations is made a breeze thanks to our friendly interface. It’s recommended that you contact us if any inquiries about the hydraulic cutting press arise, we’ll have the knowledge to answer most of your questions.

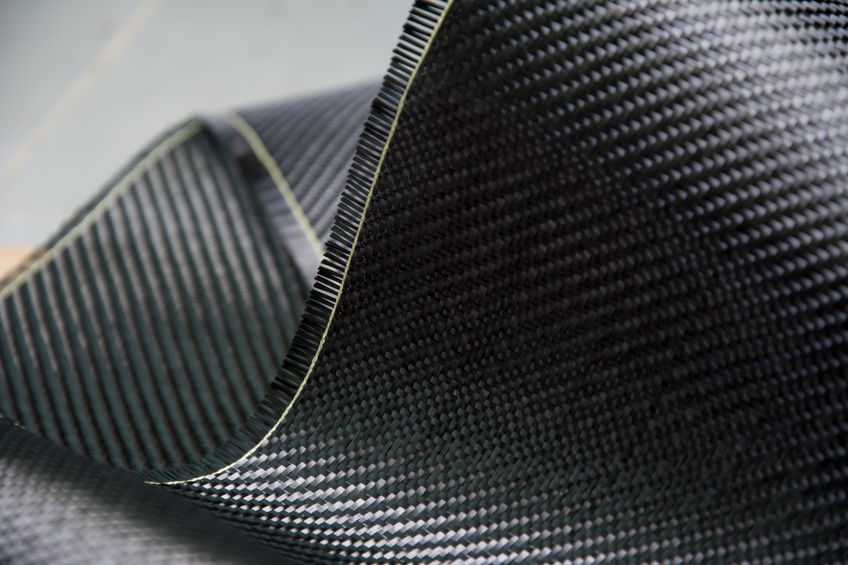

Operations related to textile usage are a line for cutting inner dashes (assists with automatic alimentation, coating of unseen areas on the press and container management), the cutting of hydraulic press (technical tools-orientated cutting of tissues and fiber) and a stamping-thermoforming line (Material transfer and production of sandwich-based materials). These textile operations allow for the finest of presses to be manufactured, they are a pivotal component of the entire procedure. You should never skip on textile work as it can severely disrupt the flow of your plan and make the machine concept obsolete. At MIB by Numalliance, great emphasis is centred on textile work because we understand how detrimental it is to a machine’s design and plan. Overall, we guarantee our customers fantastic service and equipment, so you shouldn’t be at all worried about the quality at MIB Hydro.

Français

Français